tear strength test fabric|tear resistance test for fabric : distributors 11.2 Tearing Strength—Calculate the fabric tearing strength as the average tearing force for each test direction and testing condition of the laboratory sampling unit and for the lot, to the nearest 1 % of the full-scale .

WEBpensado. Gerúndio. pensando. Indicativo. Presente. eu penso tu pensas ele/ela/você pensa nós pensamos vós pensais eles/elas/vocês pensam. Pretérito imperfeito. eu pensava tu .

{plog:ftitle_list}

SafeTTC. SafeTTC offers three easy and discreet ways to report safety concerns directly to Transit Control. Download the app from the App Store (IOS) or Google Play (Android). .

Tear strength is a material property that determines the amount of force required to propagate a tear in a fabric. It is typically measured in pounds-force (lbf) or Newtons (N) and serves as a measure of a fabric’s resistance to . At present, the most commonly used method of fabric tearing strength test is mainly the pendulum method, tongue method and trapezoidal method. Aside from these . 1.1 This test method covers the determination of the force required to propagate a single-rip tear starting from a cut in a fabric and using a falling-pendulum (Elmendorf-Type) .For most textile fabrics testing to ASTM D2261, a single column frame is appropriate as the loads rarely go above 5 kN. Instron’s Bluehill® Universal testing software offers a pre-built test method for ASTM D2261 to simplify .

textile tearing strength test

tearing strength test

Tensile testing tests a fabric’s strength and elongation properties, with two common methods the grab test ASTM D5034 and the strip test ASTM D5035. Tear testing measures the resistance of fabric to tearing using three popular . 11.2 Tearing Strength—Calculate the fabric tearing strength as the average tearing force for each test direction and testing condition of the laboratory sampling unit and for the lot, to the nearest 1 % of the full-scale .ASTM D2261 and ASTM D624 are commonly used for fabric tear strength testing. What is the difference between tear strength and tear resistance? Tear strength quantifies the force needed to propagate a tear, while tear resistance refers to .

Fabric tear strength. The tear strength of the fabric refers to its resistance to tearing force. Usually fabric tears when it is snagged by a sharp object and the immediate small puncture is .

Tear strength is the tensile force required to rupture a pre-slit woven fabric sample under controlled conditions. Edge tearing strength of paper is the load required to tear a sample over a V-notch fixture. 2.Tear strength test. a.Pendulum method. Apparatus and Material; Pendulum fabric tear strength tester (Figure 1), steel ruler, scissors, a few pieces of fabric, etc. figure 1: Elmendorf Tearing Tester . Test principle; .This test allows manufacturers to determine the strength of the sample. This test complies with the following standards: ASTM D1004 Standard Test Method for Initial Tear Resistance of Plastic Film and Sheeting, and ASTM D5587 .

Electrolytic Sensor Method services

tearing strength of fabric

Flex Durability Tester factory services

Q: What are the relevant standards of textile tearing strength testing? At present, the most commonly used method of fabric tearing strength test is mainly the pendulum method, tongue method and trapezoidal method. Aside from these three methods, there is also Wing method, rectangle method and nail method used nationally. Table 1 shows the relevant.ASTM D2261 and ASTM D624 are commonly used for fabric tear strength testing. What is the difference between tear strength and tear resistance? Tear strength quantifies the force needed to propagate a tear, while tear resistance refers to . Imagine the unwavering strength of Hercules applied to your favorite fabric. When you consider tensile strength, you're fundamentally looking at a material's ability to resist breaking under tension. High tensile strength is essential for ensuring that fabrics don't tear easily, especially when used in demanding applications like outdoor gear or heavy-duty . 1.2 This test method applies to most fabrics including woven, layered blankets, napped pile, blanket, and air bag fabrics, provided the fabric does not tear in the direction crosswise to the direction of the force application during the test. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing .

The Elmendorf Tear Strength Tester is an instrument specially used to test the tear strength (strength) of fabrics. It uses the impact pendulum method to measure tear strength, also known as the pendulum or falling weight tear strength tester. There are manual electronic tear strength testers, digital Elmendorf tear strength testers, etc.

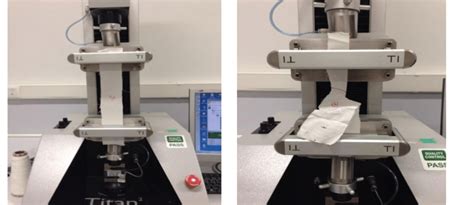

Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric. This test method applies to most textile fabrics, including those that are treated and untreated, woven, knitted, or unwoven. 1.2 Significance of fabric tearing strength test: Tear strength is particularly important in applications where fabrics are subjected to dynamic forces or sharp objects. For instance, in athletic wear, tear strength ensures that the fabric can withstand stretching and movement without ripping. Similarly, in outdoor textiles like tents or . There are two separate tear strength testing methods: tongue tear and trapezoidal tear. They both require specific preparations in order to be accurate. As the names suggest, in tongue tear tests the fabric is cut to form two tongues at the end of the rectangle, while the trapezoidal tear testing requires the material to be cut into a trapezoid .

Different Methods of Fabric Tensile Strength Test. Md. Rubel Miah Department of Textile Engineering World University of Bangladesh Email: [email protected] . Fabric Tensile Strength Test Fabric tensile strength can be tested using universal tensile strength testing equipment with suitable sample mounting jaws. The tongue tear method is often used to measure the tear force and the tear strength of a fabric specimen. This method, outlined by ASTM D2261, requires a specific sample preparation where the rectangular fabric specimen is cut to form two tongues on each end which are then placed on upper and lower grips.Once tensile force is applied, the fabric specimen . Here is the significance of tear strength according to the use of fabric in different industrial sectors. Apparel; Tear strength ensures the garment’s better lifespan and comfort. Industrial Textiles Fabric tear strength test is a very important parameter for industrial textiles that are used in construction and safety equipment. Medical Textiles

tear strength test for fabric

ASTM D2261 Fabric Tear Strength Tongue Testing Equipment. ASTM D2261 determines the tearing strength of textile fabrics by the tongue (singl. Car Seat Foam Bolster Testing . Car manufacturers are required to test their molded foam car seats to ensure safet. ASTM D4786 Stitch Tear Strength of Leather, Single Hole .

ASTM D1424 is a widespread test approach evolved by the American Society for Testing and Materials (ASTM) for determining the tearing strength of fabric using the Elmendorf tear test equipment. This method is widely recognized and utilized in various industries, inclusive of textiles, clothing, and packaging.

5.2 The force registered in a tear test is irregular, and as a consequence, empirical methods have had to be developed to obtain usable values related to tear strength. In spite of the empirical nature of the reported values, the values are considered to reflect comparative performance of similar fabrics tested and measured in the same way.

Testing Fabric Strength. To guarantee your fabric meets durability standards, various tests like tensile strength and abrasion resistance are necessary. These tests provide important insights into how your fabric will . A tear strength test is often required for woven fabrics used for applications including army clothing, tenting, sails, umbrellas and hammocks. . An increase in yarn density in a woven fabric will decrease the tear strength of a fabric as yarns are broken individually as they have more restriction, preventing yarn slide. .A tear starts with a snag on clothing etc., then the fabric has a small cut in it, so if the force continues the fabric will then tear. The cut before testing is to help with tear propagation. Q: What type of load cell to use and calibration certificate to request if we have test fabrics with tear strength between 10 and 100 newtons?

For example, with rubber, tear resistance measures how the test specimen resists the growth of any cuts when under tension, it is usually expressed in kN/m. [2] Tear resistance can be gauged via the same ASTM D 412 apparatus used to measure tensile strength, modulus and elongation.ASTM D 624 can be applied to measure the resistance to the formation of a tear .The method specifies a procedure to determine the tear strength of textile fabrics using the trouser method. A rectangular specimen is cut in the center of the shorter dimension to form a trouser shape. . Each leg of the trouser is inserted into the grip faces and pulled to tear the fabric. For this test, it is important to have an increased .

The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. The tear strength is measured as per the ASTM D412 standard test method, which is also used to measure tensile and elongation. The standard test method measures the resistance to the formation .

Seal Test / Sealing Test services

Tear strength testing is therefore considered a qualitative test to demonstrate failure mode rather than a value comparative test to allow precise comparisons of various materials. . Tear Strength of Fabric. Fabrics are materials produced by weaving together materials such as wool, nylon, and cotton. . When you consider the tensile strength and durability of fabrics, you're looking at aspects that greatly affect the lifespan and quality of your garments.Understanding how various factors like fiber type, weave pattern, and finishing processes play roles in making a fabric either resilient or prone to wear and tear is crucial.Tests such as the Martindale Abrasion Test and .

Tear test specimens are pulled on a tensile tester at a cross-head rate of 8.5 millimeters per second (20 inches per minute). . Fabric tear strength is generally susceptible to changes during processing 92 (dyeing and finishing), due to the changes in fibre and yarn friction and mobility, particularly the latter. Nevertheless, any fibre .

The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. Objectives: 1. To know about tear tester and its parts. 2. To determine the tear strength of fabric. Materials Requires: Template Scissor Fabric Elmendorf Tear Tester mm/cm Scale Machine Parts . They reveal how well a fabric can withstand daily wear and tear, including fabric tearing, abrasion, pilling, and snagging. Here's a breakdown of the most essential tests: Tear Strength Test: This measures how resistant a fabric is to tearing. You'll experience fewer rips and tears if the fabric scores high in this test.

webGet the desktop app. Download Battle.net and join a community of millions. Download .

tear strength test fabric|tear resistance test for fabric